Log Jam Chinking

FREE SHIPPING ON ALL SIZES TO CONTINENTAL USA.

Details

Free Ground Shipping

We offer free shipping for all sizes of this product shipping to the Lower 48 United States. Offer does not apply to Alaska, Hawaii, and the US Territories. Free Shipping applies to this item only and not the entire order.

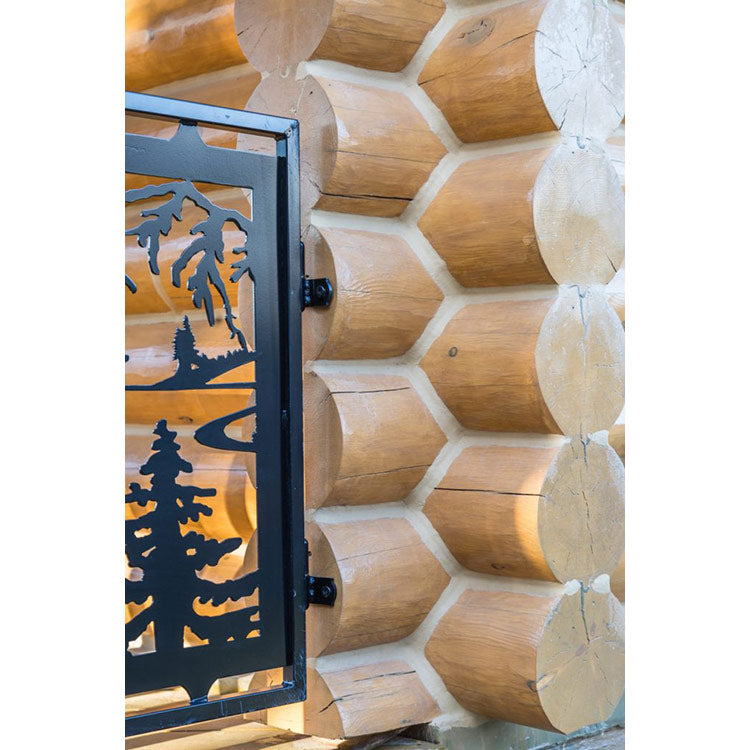

Sashco Log Jam Chinking seals the wide joints between your logs with the traditional look of mortar, but with much more elasticity. Log Jam is durable, easy to apply, and stretches up to 250%, even in joints up to 4 inches wide. It is guaranteed not to crack or peel away from logs and is the only chinking to hold a UL one-hour fire rating.

Features & Benefits

• Recognized as the industry standard for synthetic chinking

• Moves with your logs to create a permanently waterproof and weatherproof seal

• Exclusive 1-hour UL fire rating when applied in accordance with Fire Resistance Directory Design No. UL519

• Superior elasticity that prevents weather and insect infiltration

• Smooth, water-based formula allows for easy application and cleanup

• Stable through 5 freeze-thaw cycles

• Adheres well to most building materials

Where to Use Log Jam

• Interior and exterior chinking joints on log and wood homes

Where Not to Use Log Jam

• Surfaces previously coated with a waxy stain (i.e. Thompson’s Water Seal) or non-drying oil stain (i.e. WoodGuard, Q-8 Log Oil, TWP)

• Surfaces specifically designed to be non-stick (i.e. Kynar)

• Surfaces previously sealed with silicone; silicone and its residue must first be removed

Application Methods

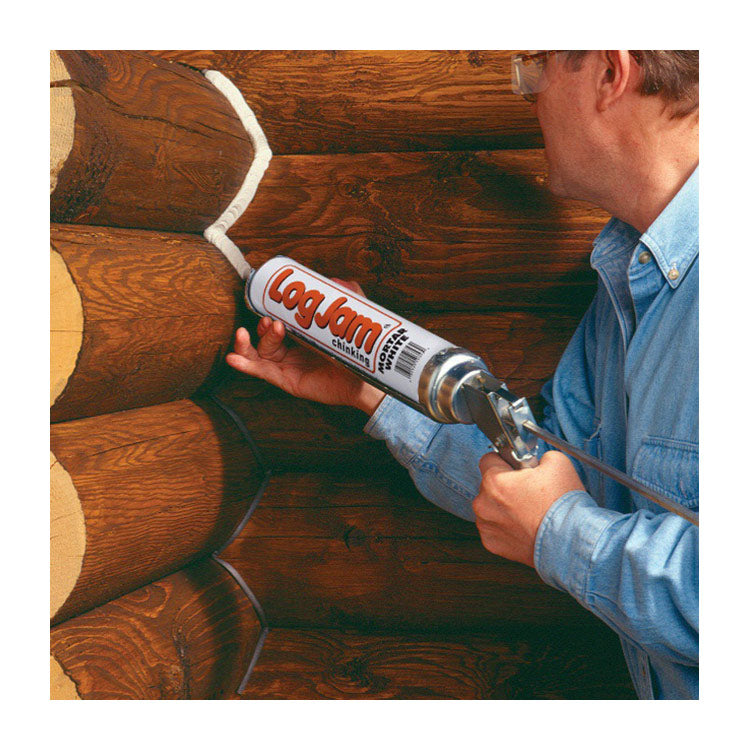

• Ratchet caulking gun (for tubes)

• Bulk-loading caulk gun with follow plate

• Grout application bag

• Chink pump

Application Details

• Ideal application temperature range is between 50-90°F

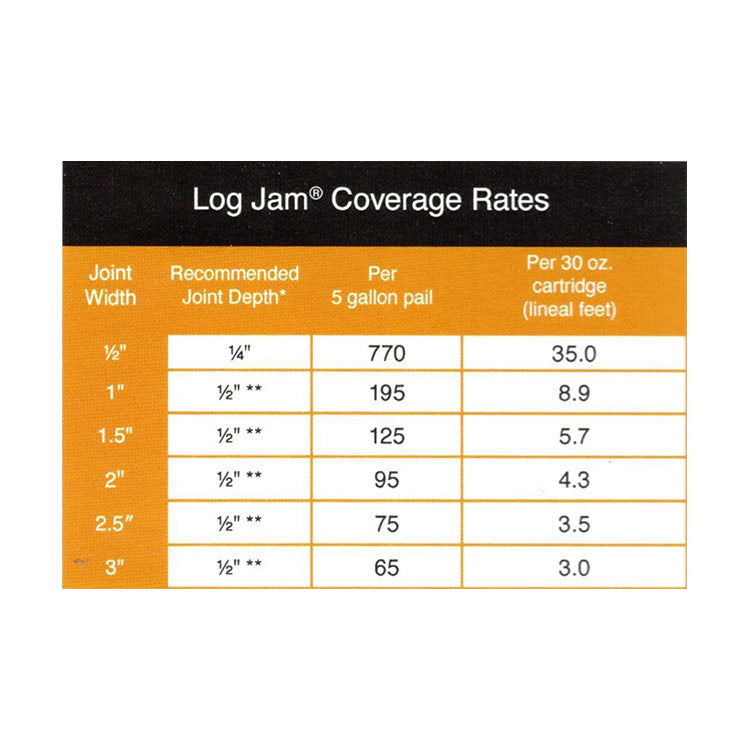

• Ideal sealant depth is 1/2 of the joint width, but no less than 1/4" and no more than 1/2"

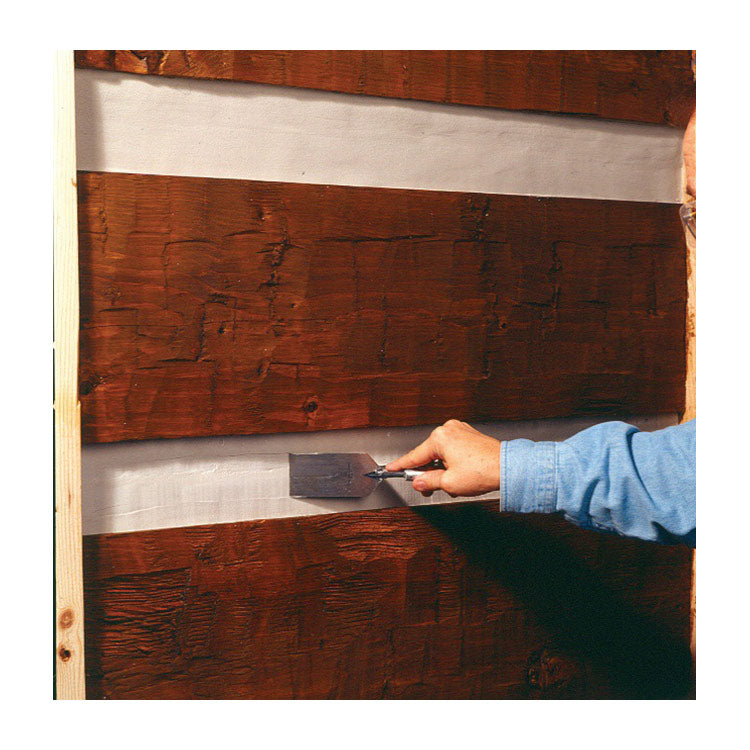

• Before Log Jam is applied, install a bond breaker such as backer rod, Grip Strip, or bond-breaking tape

• Clean up hands, surfaces, and equipment with water

• Log Jam forms a water-resistant skin approximately 1-4 hours after application

• It may be necessary to cover Log Jam with plastic sheeting if applied when rain is imminent

• Paintable with oil or latex stains after 1 week cure time

• Cure-through time: 3 weeks (1/2" thickness, 70°F, 50% relative humidity)

• If restoring Log Jam with chink paint, make sure the chinking has already cured

Sashco Log Jam Technical Guides

Log Jam Chinking Product Guide

Preventing Blisters in Chinking Material

Do-It-Yourself Chink Paint Formula with Log Jam Chinking

Log Jam Chinking SDS

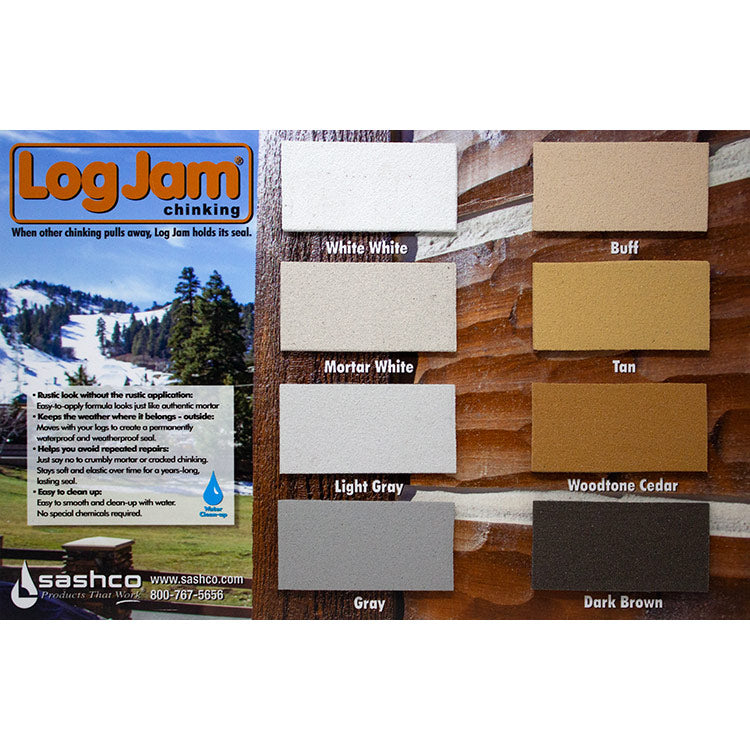

Colors:

Buff, Dark Brown, Gray, Light Gray, Mortar White, Tan, White White, Woodtone Cedar

Sashco Technical Support

If you have questions or issues regarding the Sashco line of products, Sashco Technical Support is available at 800-767-5656.

Specifications

More Information

|

Fundamental Chinking Application Guidelines Surface Preparation Cold Weather Chinking Methods of Application Tooling New Construction Joint Design Restoration Slab Siding Blisters Cleanup and Disposal |

Reviews

Product Questions

Product Questions

-

How do I apply the chinking if I get a 5 gallon pail?

The main options are a bulk gun, a chink pump, or a trowel and mortar bag. The bulk gun is the most popular of these methods. A bulk gun is a caulk gun that be loaded as needed with caulk or chinking. Bulk guns also have a variety of optional nozzles that can be used to change the tooling pattern.

Bulk guns are loaded by unscrewing the cap at the end, packing the chinking inside, and screwing the cap back on. You want to avoid getting chinking on the threads of the gun, as these are very difficult to clean. We recommend using a follow plate or a loading sleeve to make filling the bulk gun faster and cleaner.

-

I accidentally stained my chinking and I can't scrub off the color. How can I fix this?

Fresh stain that has dried can’t be scrubbed off. Your best option is to cover the stain. You can either coat the affected area with a light coat of chinking or brush over it with a coat of chink paint. Chink paint is essentially a thinned version of chinking that can be painted on as needed. Here is Sashco’s recipe for making a chink paint out of a tube of Log Jam.

-

I chinked my house 18 years ago with Log Jam. The chinking is torn away from the logs in a few places. What can I do to fix this?

If the chinking has pulled away from the logs, then it’s likely the original chinking line was too thin and it tore when the logs moved with seasonal swelling and shrinking. To fix this, you will need to cut out the torn chinking, install backer rod if needed, install new bond breaker tape, and re-chink the joint. Ensure that the chinking is between ¼” to ½” thick. Also, feather in the new chinking over the edges of the existing chinking to make a clean transition.

-

How do I keep stain off my chinking when I have to restain my home?

The answer depends on whether there is any pigment in your stain’s topcoat when you apply a maintenance coat of stain. The answer is easy if you are using a stain system that has a clear topcoat, such as Capture and Cascade. The clear Cascade topcoat won't discolor the chinking if you paint or spray it over the chinking.

If you’re applying a pigmented stain such as Transformation Log and Timber with a brush, your best option is to tape off the edges of the chinking with painter’s tape first. If you plan to apply with a spray instead, you will want to consider covering all of the chinking with painter’s tape since it is difficult to control overspray.

-

Should I apply the chinking directly onto the wood?

No, instead we recommend installing a bond breaker, such as backer rod or clear packing tape, between the chinking and wood to make maintenance easier. If you apply chinking directly to the wood and need to alter it later, it can be very difficult to cleanly cut out the problem section. If a bond breaker is installed underneath the chinking, you can simply cut the affected area at each end, which should then peel up easily.

-

When should I use chinking instead of caulk?

Acrylic latex chinking is formulated to mimic the appearance of old-style mortar in log joints. This means that chinking is thicker and has a heavier grit than nearly all log caulks. Additionally, chinking colors are designed to contrast with the logs, while log caulk colors are designed to blend in with the logs.

Chinking is a better fit when you have a wider joint (1" or more) that would benefit from extra stiffness or when you prefer the contrasting mortar-style look of chinking. -

Is there a type of stain I should use if my house has chinking?

Chinking compounds such as Sashco Log Jam are water-based so using a water-based stain is a good choice. You can definitely use an oil-based stain but you will need to be very careful when staining to prevent the oil stain from getting onto the chink. When using a water-based stain, typically the maintenance coat will be a clear finish which can be sprayed or brushed over the wood as well as the chinking without an issue. If stain does get onto the chinking, a chink paint can be used as a refresher to brighten up the existing chinking and cover any stain drips.

-

How wide of a joint can I use with Log Jam?

Sashco Log Jam recommends that the chink joint is a maximum of 4". This is to prevent slumping when applying this compound.

| Features | |

|---|---|

Chinking Base |

|

Texture |

|

Sheen |

|

Clean Up |

|

Stainable |

|

Application Range |

|

Application Methods |

|

Usage Area Type of surface where this product is suitable for use.

|

|

Freeze-Thaw Stability |

|

| Item | |

Brand |

|

Size |

Box (10) 29oz. Tubes

|

UPC |

031525503035

|

MPN |

|