HeadLOK Structural Wood Screws

Details

The FastenMaster HeadLOK Structural Wood Screw is a flat head screw engineered for a wide range of heavy duty wood construction applications including:

• Structural Insulated Panel construction

• Stress Skin/Timber frame connections

• Deck framing

• Stair stringers

• Two, three and four ply beam connections

• Hanging cabinets

HeadLOK Screw Features

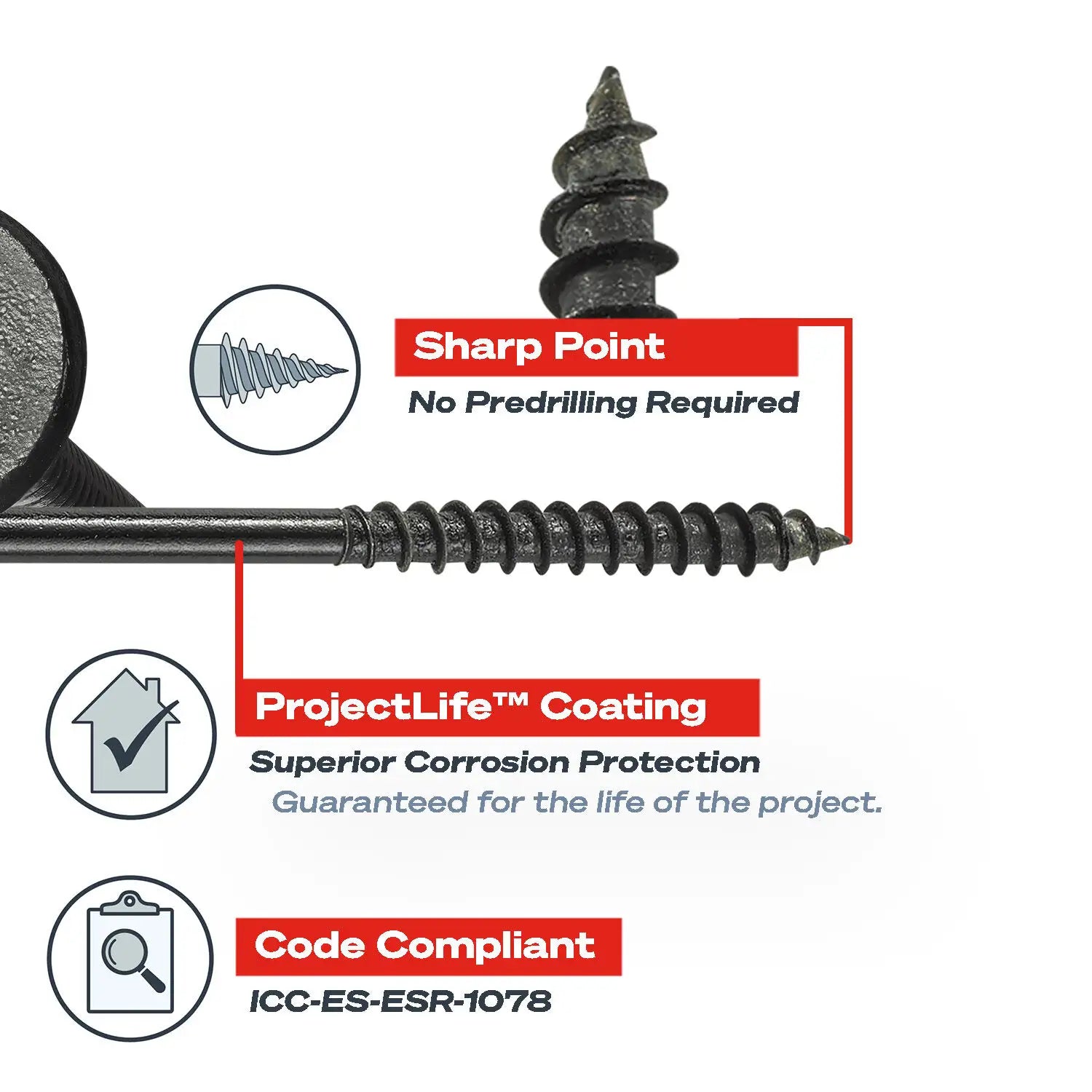

• Sharp gimlet point for fast, one step installation into wood and OSB.

• Aggressive 2” thread for holding and withdrawal strength.

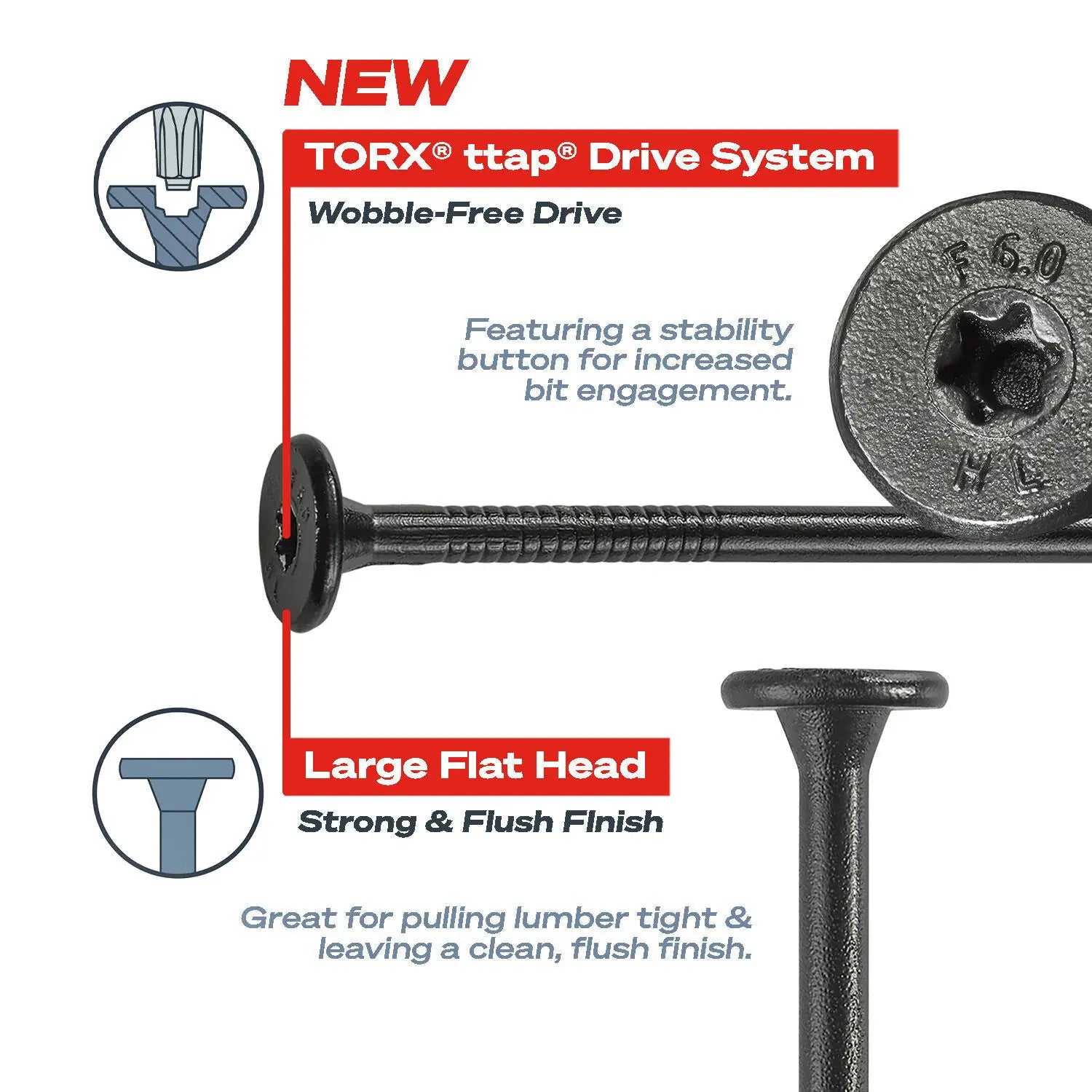

• Now with TORX ttap Drive System delivering a superior bit engagment for a stable wobble free installation.

• One Torx ttap bit is included per pail.

• Wafer head eliminates the need for a washer and offers dramatically increased pull through strength.

• Self drilling for most applications.

• Low profile head does not "Telegraph" through cover layer.

• Chamfer under head for increased strength.

• Highly corrosion resistant.

• American Made.

HeadLOK Benefits

• HeadLOK fasteners replace 3/8" lag screws for many applications.

• Complies with national building codes.

• Suitable for both pressure treated applications and exterior applications.• Wide Head for increased loads without the need for a washer.

• Specifically heat treated to maximize strength while maintaining ductility.

• 2" of thread for greater holding strength.

• Spiderdrive offers great bit engagement.

HeadLOK Screw Installation Tips

• HeadLOK should be installed using a high torque, 1/2" variable speed drill (18V if cordless).

• Drive the HeadLOK head flush to the surface.

• No predrilling required when proper end and edge distances are maintained.

HeadLOK Screw Guarantee

• HeadLOK is guaranteed not to rust or corrode for the life of the project. The fastener has also been tested and approved for use in ACQ.

• HeadLOK is not recommended for saltwater applications.

Product Resources

• HeadLOK Screw Product Guide

• FastenMaster HeadLOK Catalog Page

• OMG FastenMaster HeadLOK Guarantee of Performance

• Technical Report - Use of HeadLOK Fasteners to Attach Cladding to Wood Framing through Foam Sheathing

• Technical Report - Use of HeadLOK Fasteners to Provide Stud to Top and Bottom Plate Uplift Attachment

• ICC ES Evaluation Report

• Safety Data Sheet - Fastenmaster Fasteners

Specifications

Reviews

Product Questions

Product Questions

-

Can I still get Headlok screws with the Spider Drive system?

FastenMaster replaced the Spider Drive system on Headlok screws with the Torx TTAP system in early 2025. They no longer make a Spider Drive option.

-

Can I still get 16" Headlok screws?

Unfortunately, Fastenmaster recently discontinued the 9-1/2", 15", 16", and 18" Headlok screws.

-

What's the difference between the HeadLOK screw and the TimberLOK screw?

The head is the biggest difference between the Headlok and Timberlok screws. The Headlok has a flat head that lays flat on top of the surface of the board. The Timberlok has a hex head that countersinks into the board. Other attributes such as the shank diameter, coating, and thread length are the same.

| Product Details | |

|---|---|

Brand |

|

Brand Series |

|

Available Sizes |

|

Thread Length |

|

Thread Diameter |

|

Shank Diameter |

|

Drive System |

|

Head Type |

|

Head Diameter |

|

Point Style |

|

Coating Material |

|

SKU |

HPF278

|

UPC |

608309410348

|