Bundle #1 Grade 24" x 5/8" Western Red Cedar Hip and Ridge Joints

Please call for a custom shipping quote for pallet orders.

Details

Western Red Cedar Tapersawn Hip & Ridge Jointed Ridge Caps will give your roof line a clean and consistent look while also providing durability and beauty. Cedar shakes are lightweight, wind resistant, and provide excellent insulation. Whether you stain them or allow them to weather naturally, real cedar are a low-maintenance, practical option that will give your home the beautiful look you desire.

Features & Benefits of Western Red Cedar Tapersawn Shake Ridge Caps:

• Extreme Durability – Cedar Shakes easily withstand harsh weather conditions including heavy wind, rain, and hail.

• Longevity – Western Red Cedar is known as one of the most durable softwoods. With proper maintenance, Cedar Shakes can beautify your home for decades.

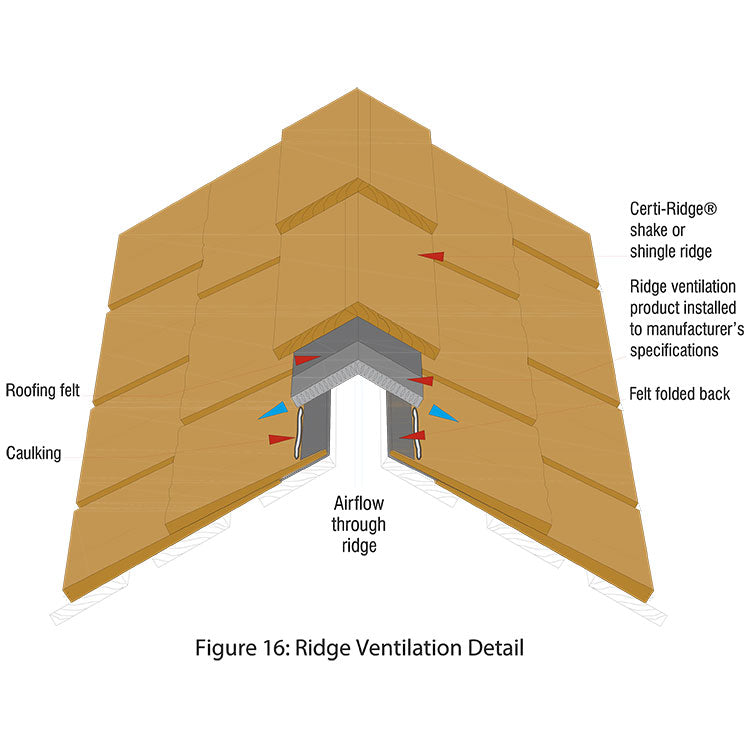

• Energy Efficiency – Cedar offers excellent insulation for your home. While maintaining a low carbon footprint, Cedar will keep your house warmer during cold months, while allowing your home to breathe and stay cooler during the warmer months.

• Termite Resistance – Western Red Cedar wood is naturally resistant to termites.

• Ease of Installation - Cedar Shakes are simple to install and come pre-bundled for easy jobsite transport.

• Versatility – Western Red Cedar Shakes can be used with many different architectural styles, affording you the option of a home covered in beautiful Cedar wood, or simply a small rustic accent area on an otherwise traditional home.

• Adaptability – Cedar Shakes are manufactured to be used on both interior and exterior wall surfaces.

Product Specifications:

• Packaging: 20 Joints Per Bundle = 16 2/3 linear feet of coverage if you use a 10" exposure.

• Length: 24"

• Grade: #1 Grade (Blue Label). Clear Heartwood, 100% edge grain, no defects.

• Texture: Smooth Sawn Texture

• Thickness: 5/8" - 3/4" thickness at the butt

• Width: No less than 9"

• Treatment: Natural - Untreated

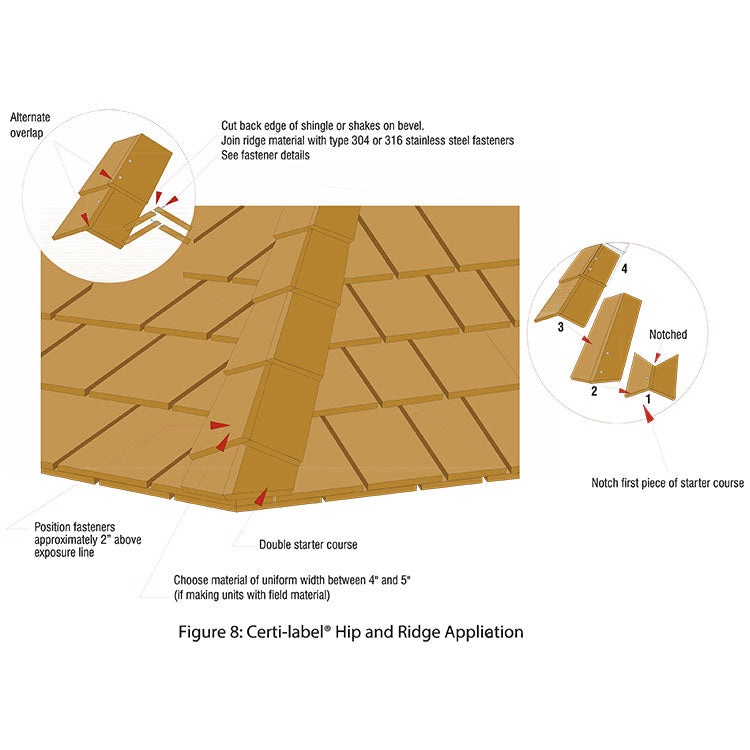

• Exposures: The Hip and Ridge exposure should be equal to or less than the exposure in the field of the roof, and should not exceed the maximum exposure for the specified length and grade.

• Roof Angle: This design of ridge cap is suitable for 4/12 to 10/12 roof pitches. It does not fit roofs with high angled 12/12 roof pitch.

Recommended Use: The appropriate Hip and Ridge unit should be selected to match the adjacent shingles or shakes. However, in many regions a Tapersawn Hip and Ridge unit is used on both shingle and shake applications. Hip and Ridge product type selection should be in accordance with the aesthetic desired.

Product Resources:

Cedar Shake and Shingle Product Selection Guide

Cedar Shake and Shingle Specification Guide

Basics Guide for Cedar Shakes and Shingles

CSSB New Roof Construction Manual

Estimating Cedar Hip and Ridge Joints:

Please ensure you have the following information when estimating roof coverage for cedar shingles:

1. Length of all hip and ridge roof joints you wish to cover measured in linear feet.

2. Application and exposure to be used.

3. Product type used.

4. Amount of product in each box or bundle.

Specifications

More Information

|

Additional Technical Resources for #1 Grade Cedar Tapersawn Shake Hip & Ridge Joints: Application Notes: Finishing Cedar Shingles: Nails: **Please Note: Some nail manufacturers offer nails specifically for wood shake or shingle sidewall application. Contact the nail manufacturer for further information to ensure the fasteners used comply with listed requirements and are correct for your application. Staples: |

Reviews

Product Questions

| Product Details | |

|---|---|

Grade |

|

Shingle Length |

|

Thickness Average thickness of shingle/shake at the butt (bottom) end

|

|

Width |

|

| Installation Details | |

Application Type |

|

Standard Sizing |

|

Exposure - Roof Refers to options on the length of the shake that can be exposed to the weather. Wider exposures yield more square feet of coverage per bundle.

|

|

Fastener - Roof |

|

Roof Angle |

|