X-100 Natural Seal Wood Protective Coating

Details

X-100 Natural Seal® Wood Preservative is an oil based, water repellent wood preservative consisting of essential wood protecting ingredients. Designed to penetrate the wood, our wood preservative protects against cracking, splitting, cupping, curling, sap stain, mold and mildew and the environmental forces of wind, rain, snow, ice and ultra violet light.

X-100 Natural Seal Wood Protective Coating is for use on all wood surfaces including cedar, redwood, pine, plywood, T1-11, cypress, fir, dimensional lumber, siding, decking, logs and roofs. X-100 Natural Seal Wood Protective Coating is available in transparent and semi-transparent stains. This transparent technology enables the natural wood grain to show through allowing for a natural wood finish.

X-100 Natural Seal® Wood Preservative Features & Benefits:

• For use when E.P.A. registered product is specified.

• Non-film forming.

• Provides resistance to wood degradation.

• Recommended for use on sidewalls, fences, roofs and dimensional lumber.

• Compatible with one-part urethane caulking and oil-based caulks.

• Long-chain oils dry more slowly allowing for deeper penetration.

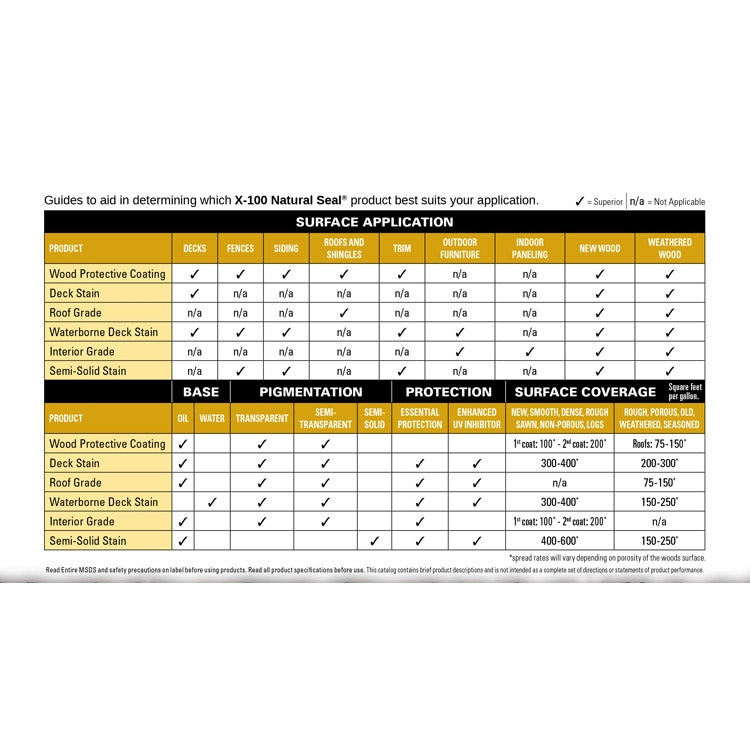

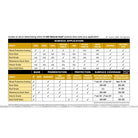

X-100 Natural Seal® Wood Preservative Coverage:

• Sidewalls: Smooth or Rough sawn lumber including logs, 1st coat 100 sq. ft. per gallon.

• Second coat - 200 sq. ft. per gallon.

• Roofs: 75-150 sq. ft. per gallon, depending on porosity of surface.

Product Resources:

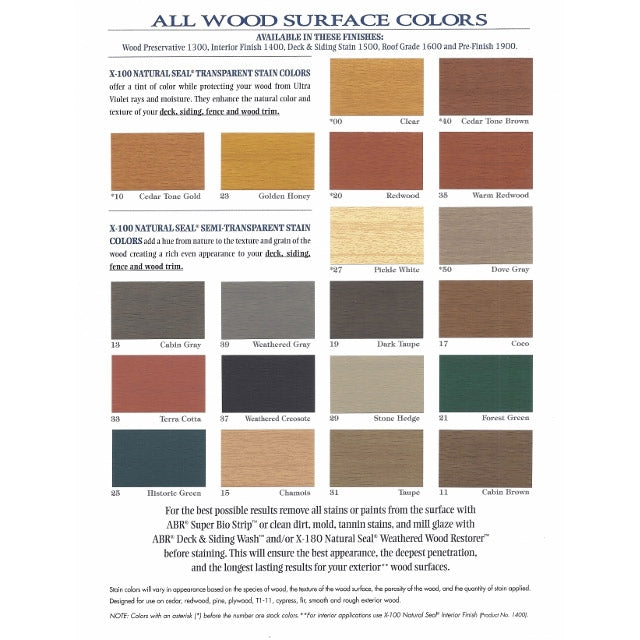

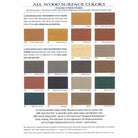

X-100 Natural Seal Wood Protective Coating Colors:

Cabin Brown, Cabin Gray, Cedartone Brown, Cedartone Gold, Chamois, Clear, CoCo, Dark Taupe, Dove Gray, Forest Green, Golden Honey, Hampton Gray, Historic Green, Neutral Tint Base, Pickle White, Red Wood, Stone Hedge, Taupe, Terra Cotta.

Specifications

More Information

|

X-100 Natural Seal® Wood Preservative Dry Time: X-100 Natural Seal® Wood Preservative Proper Surface Preparation: X-100 Natural Seal® Wood Preservative Application Methods: X-100 Natural Seal® Wood Preservative Tips for Best Performance: X-100 Natural Seal® Wood Preservative Application Instructions: X-100 Natural Seal® Wood Preservative Cleanup: |

Reviews

Product Questions

| Features | |

|---|---|

Opacity Refers to how easily one can see through the stain. Translucent means that the wood grain is easily visible through the stain. Semi-transparent means that the wood grain is obscured by the pigment in the stain but is still visible.

|

|

Stain Base |

|

Stain Type Refers to how this stain was designed to work. Coatings form a flexible solid barrier on the outside of the surface to protect from the outside-in. Deep penetrating oils normally do not form a surface barrier and protect from the inside-out.

|

|

Product Type |

|

Usage Area Type of surface where this product is suitable for use.

|

|

Application Range |

|

Dry Time |

|

Coverage Rate Coverage rate can vary greatly depending on the texture of the surface. Please see description for full details.

|

|

Coats for First Application How many coats of this stain that are normally needed for the first application over bare wood.

|

|

Coats for Maintenance How many coats of this stain that are normally needed when the stain has weathered and is in need of a maintenance coat.

|

|

Clean-Up |

|

| Item | |

Brand |

ABR Products

|

Size |

1 Gallon

|

Color |

Cabin Brown

|

UPC |

0

|