Sikkens Proluxe Cetol Log & Siding Stain

FREE SHIPPING ON 5 GALLON & 1 GALLON PAILS TO CONTINENTAL USA.

Details

Free Ground Shipping on 1 Gallon and 5 Gallon Pails

We are offering free shipping for 1 gallon and 5 gallon pails of this product shipping to the Lower 48 United States. Offer does not apply to Alaska, Hawaii, and the US Territories. Free Shipping applies to this item only and not the entire order.

Sikkens Proluxe. The same great Sikkens formula you know and trust, slightly different labels.

The high quality formula that is synonymous with the Sikkens name is exactly the same as before. Only the name is changing. You can be confident that the product is the same in the can regardless of whether the name is Sikkens or ProLuxe . Please click here, here, or here for further information from PPG on this change.

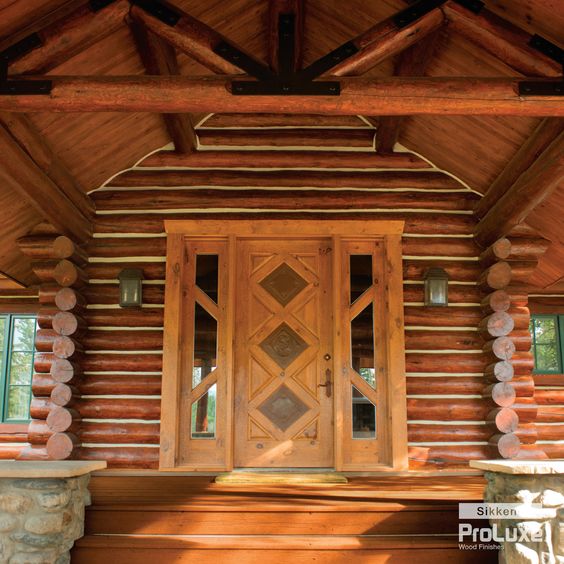

Sikkens Proluxe Cetol Log and Siding is a high-performance translucent exterior stain for log homes and wood surfaces. This alkyd high solids formulation offers optimum protection and a premium look in just two coats. The high solids alkyd resin used in Sikkens Proluxe Cetol Log & Siding is another example of Sikkens Proluxe’s commitment to providing superior quality wood coatings.

Sikkens Proluxe Cetol Log and Siding’s two-coat satin finish creates a protective film that gives siding and logs a premium furniture-like finish that allows all the natural characteristics and grain of the wood to show through. The product creates a durable surface barrier to prevent wood from weathering.

Sikkens Proluxe Cetol Log and Siding Recommended Usage

• Cetol Log & Siding works well on logs, siding, trim, beams, and garage doors. Sikkens Proluxe Cetol Log and Siding can be used on species of wood such as cedar, fir, pine, spruce, and redwood.

• Cetol Log & Siding should not be used on horizontal surfaces that may be walked on such as decks. Please check out Cetol SRD or Cetol DEK if you are in need of a premium Sikkens deck stain.

• Cetol Log & Siding is compatible over an existing Sikkens Proluxe Cetol 1 and Cetol 23 Plus system.

Sikkens Proluxe Cetol Log and Siding Features and Benefits

• High Solids Alkyd Resin - Fewer coats needed for optimum protection and premium look. Proluxe Cetol Log and Siding utilizes Sikkens Proluxe's patented Next Wave Technology.

• Translucent Iron Oxide Pigments & UV Absorbers - Combination gives high performance UV protection, preventing graying and deterioration.

• Microporosity & Excellent Flexibility – Minimizes blistering and cracking due to expansion and contraction or moisture build up.

Sikkens Proluxe Cetol Log and Siding Color Chart

Sikkens Proluxe Cetol Log and Siding Stain Sample Cans

• We highly recommend that you try a sample can of any new stain color you are considering. The finished color of translucent stains can vary substantially based on species, texture, porosity of wood, and application technique. Sampling on your own wood is inexpensive and the best way to make sure you get the color you want for your home.

• Sikkens Proluxe no longer manufactures new sample cans of Cetol Log and Siding. However, we have several colors available in the 4 oz. factory cans while supplies last. 4 oz. sample cans of all other colors of Cetol Log and Siding are packaged in-house.

Sikkens Proluxe Cetol Log and Siding Color Visualization Tool

• You can model what your home would look like with Sikkens Proluxe Cetol finishes using the Sikkens Proluxe "Color Your Home" website.

• Please note that colors render differently on different computers and may not precisely match the color of your delivered stain.

• Sample color cans are also available for purchase if you would like to test how your home will look with any particular color.

Sikkens Proluxe Cetol Log and Siding Coverage Rates

• Coverage areas per coat for Sikkens Proluxe Cetol Log & Siding as follows:

• On rough and weathered surfaces, 150-225 sq. ft./gallon.

• On smooth surfaces or hardwoods, 300-400 sq ft./gallon.

• Actual coverage may vary depending on the type, age and texture of the wood and application method.

Sikkens Proluxe Cetol Log and Siding Stain Colors:

• Natural Oak (005) - (SIK42005); Dark Oak (009) - (SIK42009); Butternut (072) - (SIK42072); Cedar (077) - (SIK42077); Natural (078) - (SIK42078); Teak (085) - (SIK42085)

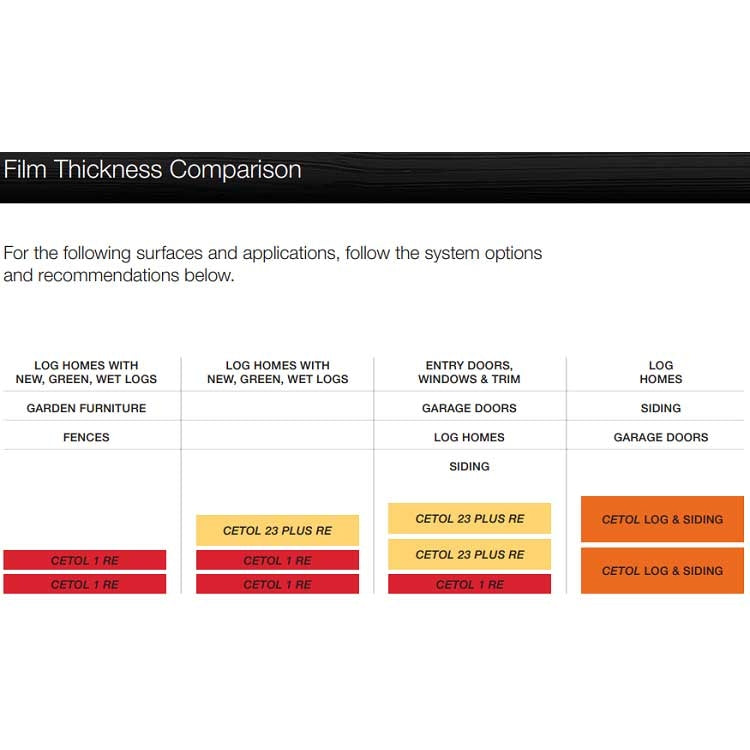

Compatibility

Sikkens Proluxe Cetol Log & Siding is compatible over an existing Sikkens Proluxe Cetol 1 and Cetol 23 Plus system.

Sikkens Proluxe Cetol Log and Siding Shipping

• Sikkens Proluxe Cetol Log and Siding may not be shipped via air transit due to D.O.T. restrictions.

Use Restrictions

Sikkens Proluxe Cetol Log and Siding is not permitted for use in the South Coast Air Quality Management District (SCAQMD) which includes all or part of the following counties of California:

• Los Angeles • Orange • Riverside • San Bernardino

2019 Name Update:

• PPG has announced that Proluxe Cetol Log & Siding Wood Finish will now be known as Proluxe Log & Siding Wood Finish. Please click here for further details on this change.

Product Guides

• Cetol Log and Siding Application Guide

• Cetol Log and Siding Tech Data Sheet

Recent PPG Proluxe Manufacturer's Rebate Forms:

• PPG Proluxe Rebate August 2025

PPG Technical Support

If you have questions or issues regarding the Proluxe line of stains, PPG Technical Support is available at 800-441-9695.

Specifications

More Information

|

Sikkens Proluxe Cetol Log and Siding Application Methods Sikkens Proluxe Cetol Log and Siding Dry Time Sikkens Proluxe Cetol Log and Siding Preparation Instructions Cleaning Recommendations: Special Notes: Previously Coated Wood - Previous stains, varnishes or sealers must be completely and thoroughly removed prior to application of Sikkens Proluxe Cetol Log & Siding. After removal of previous coatings, clean and prepare surface as specified above. New Wood - Clean and prepare all wood surfaces as specified above. Pressure treated wood must be properly seasoned, dry with a moisture content of 18% or less and free of salts and other water soluble materials before applying stain. Water- repellent treated lumber requires one year minimum of weathering prior to cleaning and application. Exotic Hardwoods - Ipe, mahogany, iron wood, tiger wood and teak woods exhibit a dense cell structure which may reduce the ability of a coating to penetrate the wood surface. Clean and prepare all wood surfaces as specified above. Immediately prior to applying coating, wipe surface with acetone. Checking Moisture Content Before Staining: Caulking Cracks, Checks, and Gaps: Sikkens Proluxe Cetol Log and Siding Application Information Sikkens Proluxe Cetol Log and Siding Cleanup & Shelf Life Sikkens Proluxe Cetol Log and Siding Maintenance Instructions Sikkens Proluxe Cetol Log & Siding Application Do’s and Don’ts Application Do’s… Application Don’ts… Additional Product Guides |

Reviews

Product Questions

Product Questions

-

Is it safe to put Cetol Log and Siding on damp or wet banisters?

I would wait until the banisters are dry. Cetol Log and Siding will have a hard time adhering to the wood if there’s moisture at the surface.

-

i am using ppg proluxe log and siding wood finish natural 078 .have put a coat of it on last year and the year before i want to keep it looking good and protected.it is still nice and shiny. should i give it another coat this year? can you put to much on? i read something about it needs to breath. is to much finish on it bad?

Thank you for your question! You will not want to recoat with this product too soon since you don't want to get the film too thick. The Sikkens stain needs to breathe so I would wait another year or two before considering recoating the home.

-

Can the Cetol Log and Siding stain be used on the horizontal surface of a deck and stairs? How about on the rails and balusters?

The Sikkens Log & Siding is intended for vertical surfaces and not to be used as a deck stain. I would recommend that you consider the Sikkens Cetol DEK stain which is used for decks with the same appearance as the Log & Siding. The Log and Siding or the Cetol DEK can both be used on the railing and pickets.

-

Can you use on previous treated log siding with TWP

Sikkens Log & Siding is not recommended to applied over any stain other than as a recoat over existing Log & Siding. You could have a possible adhesion issue if applied over any other stains whether it is oil or water based.

-

Can I purchase PPG Log and Siding by the quart? My colors are 078 and 005. I have purchased the maintenance coat from you several years ago .

I'm sorry, PPG doesn't make the Log and Siding in quarts. You may want to consider getting several of the 4 oz. sample cans if you need a bit less than a 1 gallon pail.

-

Is the Natural color clear?

Sikkens Log & Siding Natural is not a clear finish. It does have pigment in a honey tone and is highly recommended to purchase a sample can to test prior to purchasing. Sample cans are available for purchase.

-

When should do a maintenance coat of Log and Siding stain?

Sikkens Proluxe Log & Siding has an excellent longevity but you should still start checking your home after year three to make sure you don't have any cracking and peeling especially on the south and west sides of the house. Those are the two sides that typically get the most sun and weather exposure. I would consider treating those areas with a maintenance coat especially if you see the sheen level dulled down. This is an indication that the house is getting in need of a new coat of either the stain or the clear Sikkens Cetol Maintenance.

-

What strippers work with Sikkens?

The best stripper that we have found that works well with removing the Sikkens stain is Expert Clean & Bright Wood Stripper followed by Expert Clean & Bright Wood Brightener. Since the Sikkens products are oil based, it takes a very strong stripper to remove the coating. The Expert line has shown us the best results in removing this product.

-

Can you mix a custom color of Cetol Log and Siding?

Sikkens Proluxe Log & Siding comes in manufactured colors and is not able to be custom mixed. But you can use multiple colors within the Log & Siding stain line to create your own custom color. Just be sure to record your ratios if using two colors for custom blending.

-

Is this called Transparent Satin or Cetol Log and Siding?

The true product name is PPG Proluxe Log and Siding Wood Finish. It's easy to confuse because the "Transparent Satin" descriptor is printed larger on the label than the true name.

-

Hi, I would like to finish a redwood picnic table that has been outside in the shade for 1 year. It is has never been stained or finished. Is the Cetol log and siding stain the best, and which color would give it the most natural look? Thank you!

Cetol Log and Siding would be a very good finish for this purpose. We have several others that would do a good job as well.

It can be difficult to predict which color will work out the best with translucent stains, but if it were my table I would probably start consideration with the Cedar (077) or Teak (085) colors as they are already tinted similarly to redwood lumber.

Depending on the situation, you may want to consider trying sample cans of stain on the table to see what you like best. -

I'm in a 12 yr old old cabin previously stained with Cabot Australian Timber Oil (Mahogany Flame). I don't know last date of stain, but it is minimum 4-5 yrs old. Natural Pine wood color shows in places & I can now scratch off color in high heat exposed places. It's too much orange for me. The covered North face porch is ok. Will a light brown Sikkens cover & correct the current conditions? Which product? Where can I buy it?

It sounds like your current stain is showing typical wearing patterns.

Unfortunately, I cannot recommend the Sikkens Proluxe products in this case. Their product line is heavy in the orange tones and they do not have a light brown color. Additionally, Sikkens Proluxe wants their product to go over clean, bare wood, so they would not warranty it if you were to stain it over any remaining Australian Timber Oil.

I would recommend calling a local Cabot dealer to see if they have a lighter brown color that can be used as a recoat instead of the Mahogany Flame. -

How long will this last if I need to store it?

All of the Sikkens Proluxe finishes in their Cetol line (such as Cetol DEK and Cetol Log and Siding) feature a 5 year shelf life when unopened and an 18 month shelf life after opening.

That said, there are some things you can do to prolong the storage life of these products. The most important factor is that these finishes are formulated to react with oxygen. You need to remove oxygen from the storage container to prevent this reaction. The most common method is to size down the container to remove as much head space as possible. We recommend metal containers in 1 gallon and 1 quart sizes. Glass mason jars also do a good job of removing oxygen, but we recommend extra caution with glass to ensure the container doesn't break. Do not use plastic containers as these finishes will compromise the containers over time and make them prone to burst. It's always good practice as well to label the container with the product name, product color, and the date it was stored.

If you size down the container and there is still some head space, we recommend spraying Bloxygen in that open space. Bloxygen produces essentially a blanket of inert Argon gas that settles below the oxygen and will not react with it or allow it to reach the paint surface.

Both of these techniques should be very helpful in prolonging the life of any leftover stain that you have to store. -

I've been using Sikkens stain for a number of years. The label has always said it is a "Translucent" stain. I just got a new pail with the PPG branding and it now says that it is "Transparent". Have they changed the product? Is it still the same thing?

Thank you for your question. I certainly understand your confusion. We called PPG for clarification when we first encountered this on their cans that arrived with the new labels. We spoke directly with the Sikkens ProLuxe chemist and were assured that none of the products had changed. He told us that the change in wording was simply to bring the descriptive language used with the Sikkens ProLuxe line into conformity with that of PPG's other stain brands.

In this case, PPG uses the word "Transparent" to describe a finish in which you can see the wood grain clearly through a pigmented stain. Akzo Nobel, the prior owner of the Sikkens Wood Finishes brand, uses "Translucent" to describe the same thing. PPG simply altered the Sikkens ProLuxe descriptor on the labels and did not make any changes to the product formulations. -

Is this oil base or water base?

Cetol Log and Siding is an oil base stain.

-

What does SRD & RE mean? Is there a difference between Cetol 1 SRD RE & Cetol 1 RE? I'm trying to find a near match in 077 Cedar to the old Cetol 1.

Sikkens definitely uses their share of acronyms, which can make things confusing.

The SRD in Cetol SRD is short for Siding, Rails, and Decks. SRD is essentially a one-coat all-purpose wood finish, which is reflected in its name.

The RE you find on several of the products is short for Reduced Emissions. Some time back Sikkens formulated alternate versions of several of their oil based products to have lower levels of Volatile Organic Compounds (VOC's). As EPA rules have become steadily more stringent, Sikkens has discontinued production of the standard formula versions and is now producing only the Reduced Emission versions in Cetol 1, Cetol 23, and Cetol Maintenance. Both standard and RE versions are still available in Cetol SRD.

The colors are keyed the same from Cetol 1 to Cetol 1 RE, so I believe we can help you in matching your old finish. Please don't hesitate to call or email us if we can help you. -

Can you use Cetol Log and Siding over Sikkens 123?

Sikkens reports that both Cetol Log and Siding and Cetol Maintenance are compatible over an existing Cetol 1/23 system. However, Cetol 23 is not compatible over either Cetol Log and Siding or Cetol Maintenance. If your home has Cetol 23 right now, in most cases you are better off staying with Cetol 23. Cetol 23 cheaper than either Log & Siding or Maintenance and it doesn't present any concerns about compatibility. However, if you are dissatisfied with Cetol 23, either of these stains will provide you another option for your maintenance coats.

-

I'm using Sikkens Log and Siding stain on my house. Which one will with stand the sun and weather the best and last the longest, a light stain like cedar or a darker stain like teak?

In general, a darker color will last longer than a lighter color of the same stain. That said, I wouldn't expect more than a 10%-15% difference in longevity with Cetol Log and Siding even from the lightest color (Natural Light) to the darkest color (Dark Oak). Cedar is a bit lighter than Teak with less pronounced red tones, but the two are very compatible. I would expect Teak to last a little longer between maintenance coats, but not by a lot.

-

Does Sikkens Cetol Log & Siding exterior stain siding need a Mildewcide added to the stain?

It isn't necessary in most regions, but if you are in a high moisture area you may want to consider using one. If you do use the mildewcide, be sure and use it only in the last coat of Log & Siding.

-

We have bare wood timbers open to weather and it is winter (cold Feb.). How warm does it need to be to get a first coat of log and siding stain on?

Sikkens Log & Siding stain is an oil-based stain which needs the air temperature between 50 and 90 degrees while the stain is still tacky. I would recommend that you wait a little longer until the weather is better and the temperatures are more consistent.

| Features | |

|---|---|

Opacity Refers to how easily one can see through the stain. Translucent means that the wood grain is easily visible through the stain. Semi-transparent means that the wood grain is obscured by the pigment in the stain but is still visible.

|

|

Stain Base |

|

Stain Type Refers to how this stain was designed to work. Coatings form a flexible solid barrier on the outside of the surface to protect from the outside-in. Deep penetrating oils normally do not form a surface barrier and protect from the inside-out.

|

|

Product Type |

|

Sheen |

|

Usage Area Type of surface where this product is suitable for use.

|

|

Coverage Rate Coverage rate can vary greatly depending on the texture of the surface. Please see description for full details.

|

|

Coats for First Application How many coats of this stain that are normally needed for the first application over bare wood.

|

|

Coats for Maintenance How many coats of this stain that are normally needed when the stain has weathered and is in need of a maintenance coat.

|

|

Clean-Up |

|

| Item | |

Brand |

Sikkens Proluxe

|

Size |

1 Gallon

|

Color |

Butternut (072)

|

Part Number |

|